New Breakthrough in Waste Heat Recovery Technology

Revolutionizing Heat Pipe Design with Loop Architecture

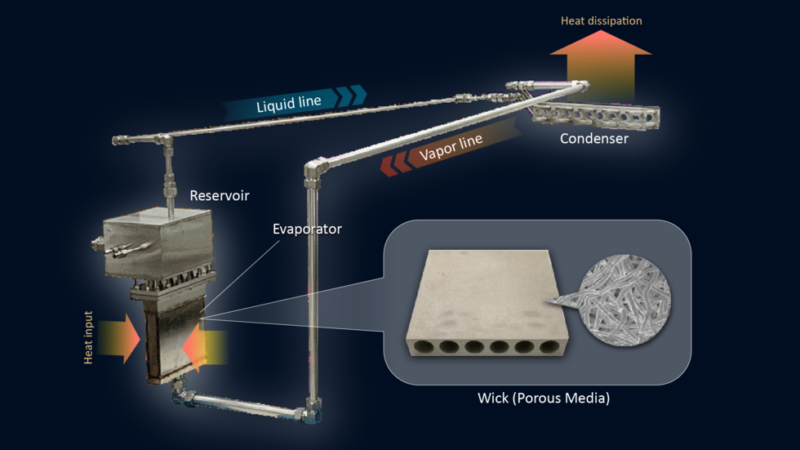

A research team at Purdue University’s School of Engineering and Applied Sciences has recently made significant advancements in developing a heat pipe design, known as the Revolutionary Loop Heat Pipe (RLHP), that can transport massive amounts of waste heat – 10 kilowatts, to be exact – without consuming any electricity in the process. This technological innovation paves the way for energy-efficient systems to reduce wasted heat energy globally.

Understanding Heat Piping: The Science behind

Traditionally, heat pipes relied on gravity-assisted transportation of heat or the vapor compression principle, which presented limitations in capacity and complexity. The development of Loop Heat Pipes sought to simplify and increase capacity, effectively resolving the former’s energy requirements and transportation issues. RLHP achieved this milestone by designing the pipe configuration as a complete loop:

Components:

-

Adaptive Conduits: Made from various materials (insulating metals, thermal shock-resistant ones, and alloys), allowing for effective flow, scalability, and mechanical durability. These conduits accommodate capillary wick structures embedded within their thickness.

-

Expansion Volute: Entrained at various intervals within each conduit portion, creating expansive surfaces fostering gas separation as pressure buildup.

- Internal Flow Regulation Devices: Configurated w.r.t piping arrangement ensuring effective condensing zones’ activation

To create such condensing systems within pipes,

- Fulfilmena Materials used

Condenser fluid at specific surface conditions creates controlled

Condensing temperatures further influence on temperature changes that help flow of internal medium in reverse, back-up pressure release from volume with volume increases due

Purifier materials ensure cleaning for more efficiency

_2.png?w=150&resize=150,150&ssl=1)

_1.png?w=150&resize=150,150&ssl=1)

_1.png?w=150&resize=150,150&ssl=1)

_1.png?w=150&resize=150,150&ssl=1)